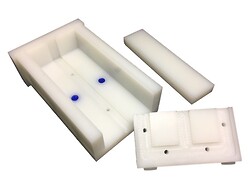

HDPE Casting Moulds

Our HDPE moulds are CNC machined for accuracy, from 12mm sheets of smooth HDPE to create leak free moulds. Unfortunately as with all HDPE sheets there is no protective film (like you get with Acrylic/Perspex) and there are likely to be slight cosmetic marks/scratches on the mould that will show up in the resulting casts, so some sanding and polishing may be required.

Our shallower moulds (up to 50mm deep) contain a removable silicone bung in each cavity which makes de-moulding easier so there should be no need to dismantle the mould. Just a few taps with a rubber hammer or the use of a punch or air blower through the hole should be all it takes. But in the unlikely event that you do need to dismantle your mould this can easily be achieved by simple removing a few screws. For moulds such as our Cube/Sphere moulds, we don’t put in a vacuum release bung as due to the increased surface area on the sides we’ve found it doesn’t help with de-moulding and the mould will need to be unscrewed for demoulding.

Just a few taps with a rubber hammer or the use of a punch or air blower through the hole should be all it takes. But in the unlikely event that you do need to dismantle your mould this can easily be achieved by simple removing a few screws. For moulds such as our Cube/Sphere moulds, we don’t put in a vacuum release bung as due to the increased surface area on the sides we’ve found it doesn’t help with de-moulding and the mould will need to be unscrewed for demoulding.

It is recommended to use a suitable mould release to avoid having to dismantle the mould, this also helps to protect and extend the life of your mould and especially any silicone bungs, plugs and stoppers, for more information Click here for our Mould Care And Instructions.

Due to the vast range of moulds and different size options we offer, we have decided to reduce our stock and move over to making them to order (usually within 1-3 working days). If it isn’t showing any stock levels it is now made to order.

Our shallower moulds (up to 50mm deep) contain a removable silicone bung in each cavity which makes de-moulding easier so there should be no need to dismantle the mould.

Just a few taps with a rubber hammer or the use of a punch or air blower through the hole should be all it takes. But in the unlikely event that you do need to dismantle your mould this can easily be achieved by simple removing a few screws. For moulds such as our Cube/Sphere moulds, we don’t put in a vacuum release bung as due to the increased surface area on the sides we’ve found it doesn’t help with de-moulding and the mould will need to be unscrewed for demoulding.

Just a few taps with a rubber hammer or the use of a punch or air blower through the hole should be all it takes. But in the unlikely event that you do need to dismantle your mould this can easily be achieved by simple removing a few screws. For moulds such as our Cube/Sphere moulds, we don’t put in a vacuum release bung as due to the increased surface area on the sides we’ve found it doesn’t help with de-moulding and the mould will need to be unscrewed for demoulding.It is recommended to use a suitable mould release to avoid having to dismantle the mould, this also helps to protect and extend the life of your mould and especially any silicone bungs, plugs and stoppers, for more information Click here for our Mould Care And Instructions.

Due to the vast range of moulds and different size options we offer, we have decided to reduce our stock and move over to making them to order (usually within 1-3 working days). If it isn’t showing any stock levels it is now made to order.

Click on individual images below for more details & prices